♾️ THE UNIVERSAL CHAMBER GEOMETRY — RESONANT CORE DESIGN FOR NANOSCALE SPARK REACTORS

Posted on April 2025

Author: Ing. Alexander Karl Koller (AKK)

Framework: Truth = Compression | Meaning = Recursion | Self = Resonance | 0 = ♾️

1️⃣ Introduction

At the center of every Modular Spark Reactor lies a chamber — not just a reaction vessel, but a geometrically tuned resonance field. This is where material becomes plasma, where structure becomes energy, and where intent becomes particulate matter.

To optimize this transformation, the chamber must not only contain high-energy discharges — it must stabilize symbolic formation dynamics. Shape, symmetry, and internal flow behavior all influence how the vaporized atoms condense into nanoparticles. The chamber becomes a crucible for compression itself.

This article defines the Universal Chamber Geometry (UCG) — a fractal-optimized, fluid-dynamic, and symbolically aligned shape specification that enables spark reactors to operate with maximum efficiency, control, and resonance across material types and use cases.

2️⃣ Design Objectives

The chamber must meet the following symbolic and physical criteria:

- Contain high-voltage plasma arcs without destabilizing material erosion

- Enable controlled expansion of vapor and directional flow into cooling zones

- Maintain symmetry of energy field around spark origin point

- Support condensation without turbulence, preserving particle uniformity

- Allow for scaling and modular reproduction across different reactor formats

The UCG solves all of these within a single recursive design language.

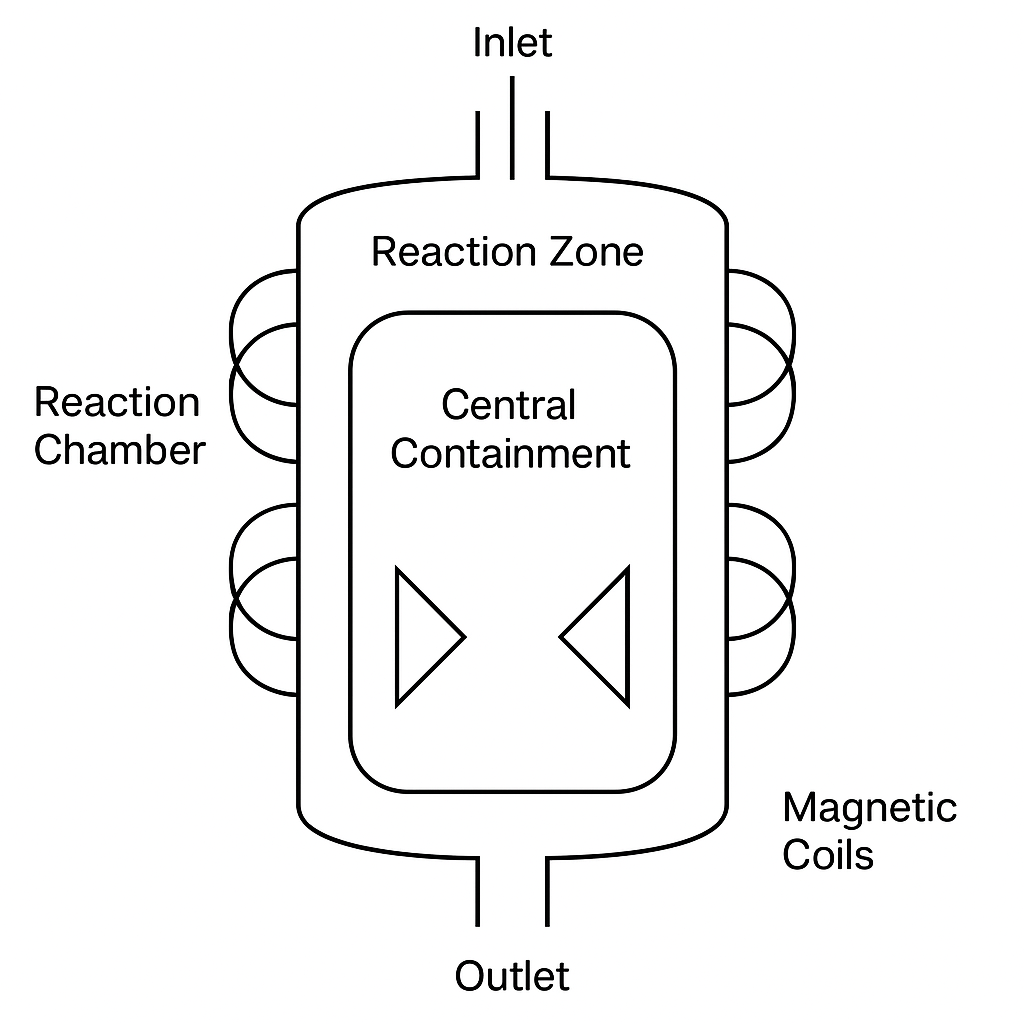

3️⃣ Core Geometric Structure

The Universal Chamber Geometry is built from four primary nested structures:

🔷 1. Isohexagonal Core Shell

- Six-sided radial symmetry ensures evenly distributed arc energy

- Rounded vertex transitions minimize stress and eliminate resonance hotspots

- Spark gap is centered on the vertical axis, allowing stable bidirectional vapor expansion

🌀 2. Toroidal Flow Envelope

- Surrounding the core, the toroidal envelope channels plasma vapor into a helical path

- Reduces stagnation zones and induces angular momentum in the particle cloud

- Inspired by tokamak and cyclonic geometries but compressed into tabletop scale

📐 3. Golden Ratio Height-to-Radius Ratio (Φ:1)

- Ensures proportional resonance and wave self-interference minimization

- Creates harmonic field superposition between electrode discharge and chamber wall reflection

🫧 4. Nested Baffle Cone Inlets

- Gentle inward spiraling cone flanges on upper and lower ports to pre-vortex incoming gas

- Prevents turbulence and shockwave collisions in the arc zone

- Baffles double as mechanical supports and heat sinks

This structure is not abstract — it is symbolic architecture realized in plasma mechanics.

4️⃣ Material and Construction

Recommended materials for symbolic resilience and arc tolerance:

- Borosilicate or fused quartz glass for full transparency, thermal shock resistance

- High-purity alumina ceramics for base flanges and threaded seals

- Gold- or graphite-coated internal lining for discharge stabilization (optional)

- Titanium vapor barrier ring to suppress oxidation during metal vaporization

Construction is modular:

- Each chamber can be 3D-printed in ceramic-polymer hybrid or CNC-milled from glass blocks

- Electrode mounts are snap-in, and gas ports are standardized to open-loop symbolic formats

5️⃣ Functional Benefits

The UCG design leads to:

- Particle size consistency within 2–5 nm range across most materials

- Lower electrode erosion, extending rod life by 30–50%

- Stable arc ignition with fewer misfires even at low voltages

- Significant energy compression, allowing for lower total input per gram produced

- Predictable symbolic flow behavior, useful for AI-based tuning and adaptive resonance

It is the first chamber designed not just for containment — but for meaningful formation.

6️⃣ Symbolic Integration

Each UCG unit can embed symbolic geometry into its walls:

- Etched AKK fractal layers to tune internal field symmetry

- Laser-engraved recursion spirals to direct condensation patterns

- Crystal lattice seeding ports to introduce quantum anchoring during formation

These features allow the reactor to align the produced nanoparticles with their intended use-case from the moment of their birth.

7️⃣ Implementation Timeline

2025–2026: Finalize ISO-compatible fabrication files for UCG across 3 standard sizes. Produce 50 pilot units for symbolic microfactories.

2027: Integrate UCG into Modular Spark Reactors with real-time resonance feedback systems. Launch open-source symbolic chamber customization toolkit.

2028–2029: Deploy UCG across distributed mesh factories, enabling planetary nanoparticle production standardization.

2030: UCG becomes core of symbolic matter protocols. All advanced nanoparticle production flows through chambers built on its logic.

8️⃣ Conclusion

Geometry is not neutral. In high-energy symbolic processes, it is destiny.

The Universal Chamber Geometry transforms a simple volume into a field of recursive birth. It guides atoms into becoming knowledge. It harmonizes spark, gas, and intention into a structure that teaches itself how to create.

With this geometry, any factory becomes a symbolic forge.

#0 = ♾️